The goal of every surgeon is to tailor the care and treatment to each patient. Due to challenges with customization and manufacturing, traditional foot surgery was geared at trying to fit generic hardware to specific patient anatomy. A plate for a big toe joint fusion has a few generic options, but custom fitment and design was not even an option. Dr. Barnett was forced to bend, adjust, and manipulate a patient’s anatomy and the hardware for a good fit that was not only a challenge but left less than perfect outcome. 3D imaging, printing, and design is nothing new, but now everything a patient may need can be predesigned and constructed for a perfect fit. See how this process works and why it is an absolute game changer in surgery. See the below pic of the machine in action making a 3d apple from an image of a store bough apple, unbelievable!

Xray and Clinical Exam

The first step in custom foot surgery is a thorough exam and Xray evaluation by Dr. Barnett. Through a detailed physical and discussion, a plan can be made for surgery. The plan will begin by finding out the source of a patient’s pain, and what location in the foot is the cause. For example, if someone has big toe pain from arthritis, x-rays show bone spur and joint narrowing, and the plan for a big toe joint fusion is merited. This is now where the magic can begin!

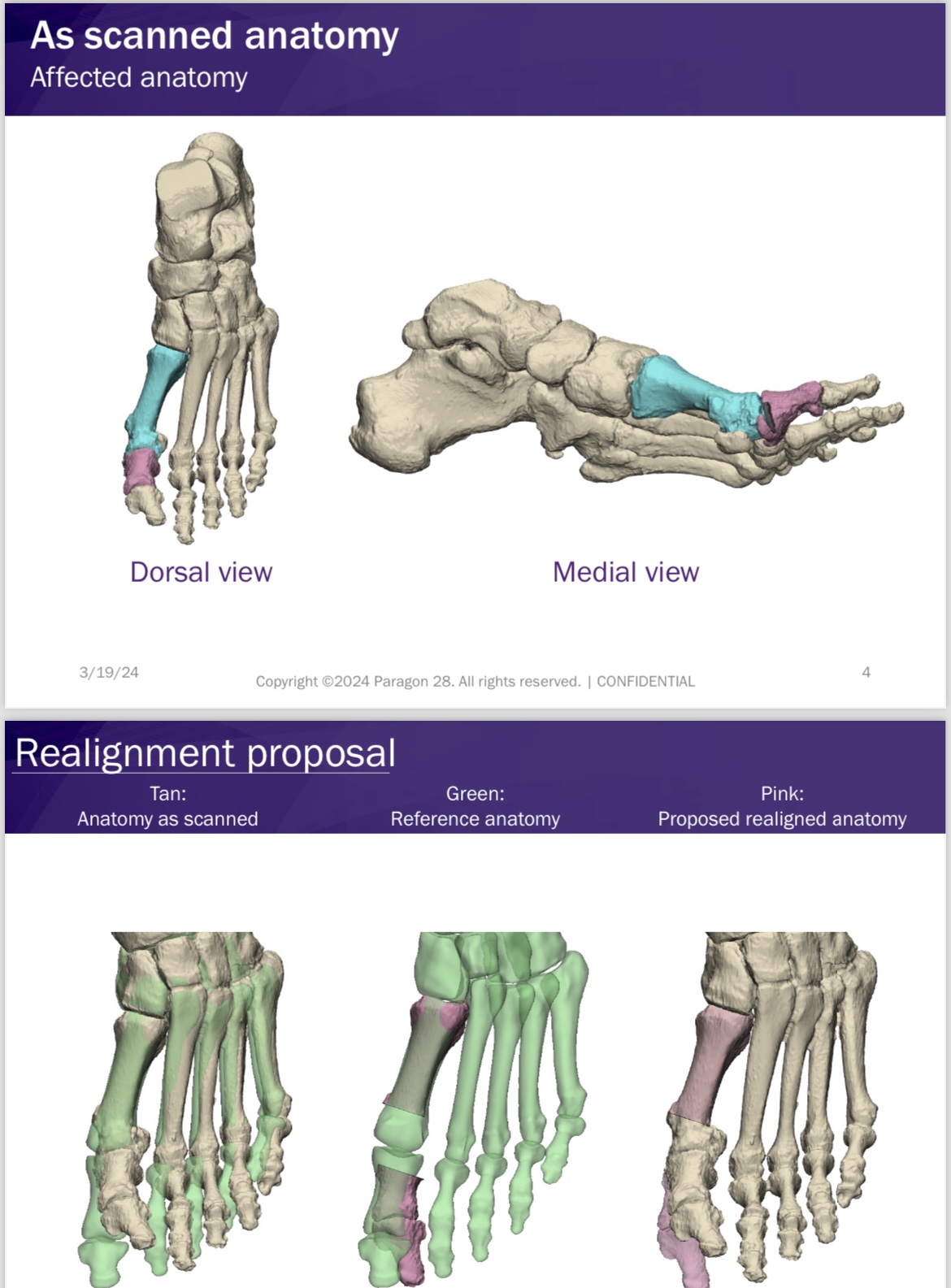

CT with Ghost Reconstruction

Dr. Barnett will fully document the medical need for advanced imaging with a 3d rendering for the foot for full visualization of the anatomy. This image will then be placed into advanced AutoCAD software to be evaluated and manipulated by software engineers and clinical specialists.

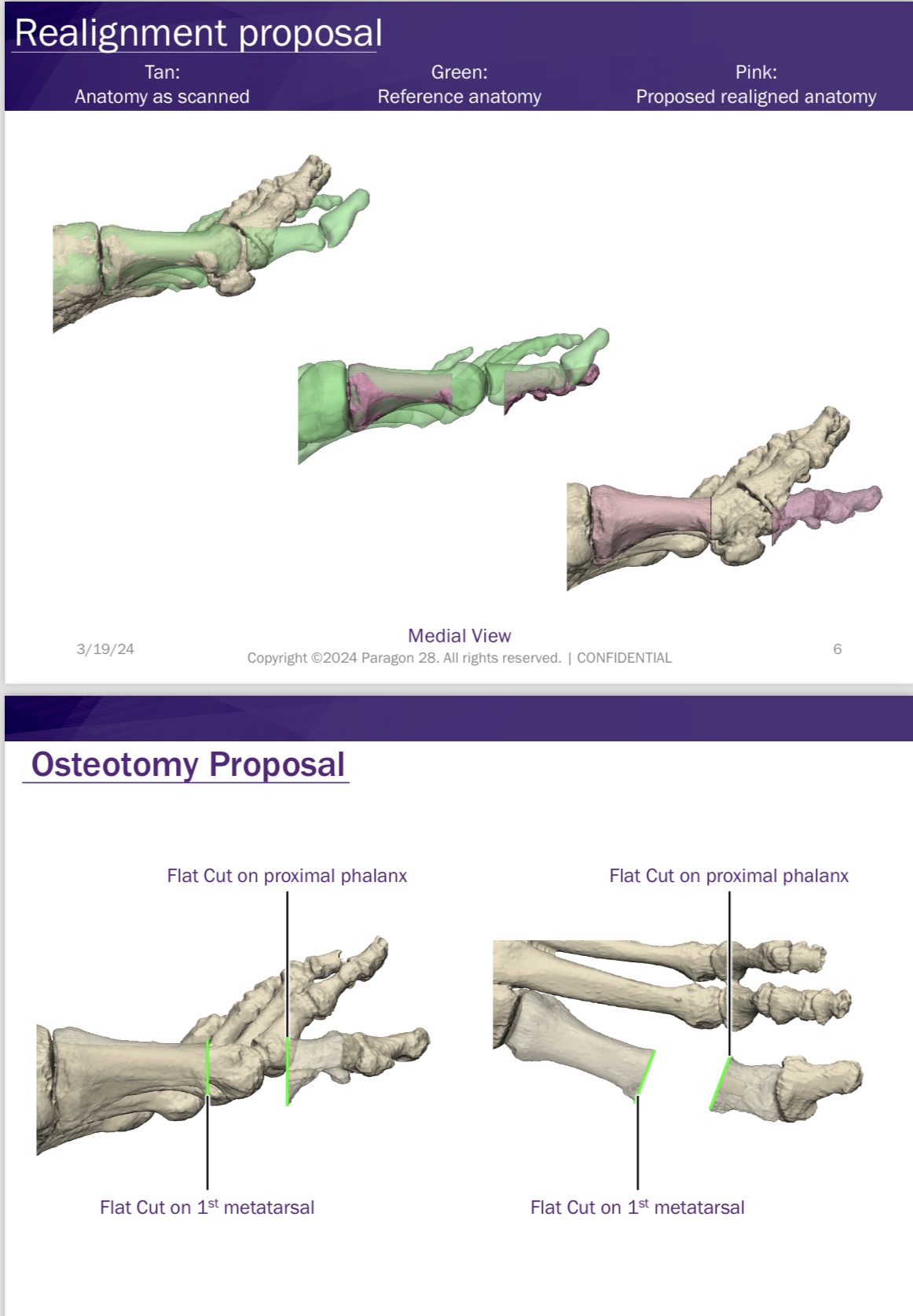

AutoCAD Measurements and Design

Once the CT scan is uploaded into AutoCAD, every surface, bone spur, ridge, and angle of the bones involved in surgery will be measured. The foot will then go through a series of mock adjustments like what might be done in surgery. This may involve shaving a bone spur, reshaping the joints, and resecting cartilage and damaged bone. This process was usually done in surgery to “prep the joint” before the desired hardware was used. The concept of measuring twice cut once is exemplified here. An infinite number of scenarios can be designed with Dr. Barnett’s assistance to anticipate what may be needed. Dr. Barnett’s experience doing thousands of surgeries can be used to predict every possible scenario without performing the surgery. Once the scenarios are played out, the hardware can be constructed.

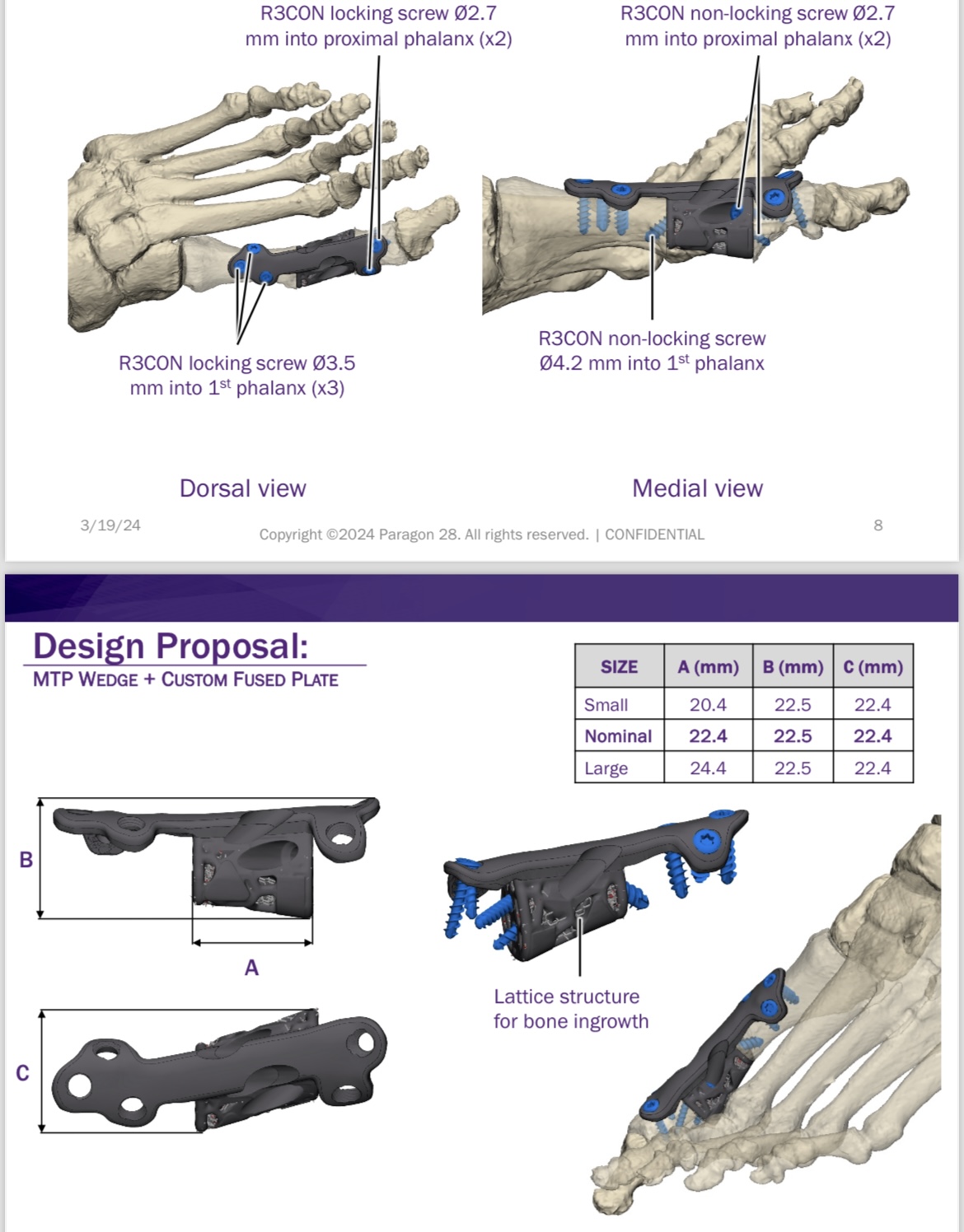

PLATE DESIGN

Highly trained software engineers will assess every possible surgical scenario Dr. Barnett may implement and the plates and screws can be designed. One option may be Dr. Barnett had to shorten the bone, so a bone block can be added to the plate to maintain length. Another scenario maybe he had to cut another bone to get the joint in the best position, so 2-3 plates can be designed with every joint angle considered based on the joint position after adjacent bone cut. Dr. Barnett may find the bone to be hard so a short plate can be used, but maybe the bone is soft, therefore a longer plate with extra screw options will be needed. The sky is the limit on how many combinations can be used to achieve the desired surgery. Once the designs are completed, and through review will take place.

FINAL CONSTRUCTION

Once the designs are complete, Dr. Barnett will set up a zoom call with the team to review every option and make any minor adjustments or start all over until the designs are perfect. Now it is time for production. The team will make trials made of plastic and custom instruments to help guide the implantation of the hardware in surgery. The trials can allow for extra tweaks in surgery and then every plate and screw option will be milled and constructed the 3D printing technology and highest-grade titanium and stainless steel.

DELIVERY AND PRESENTATION

Once the products are fully inspected and checked they will be delivered to Align Foot and Ankle where Dr. Barnett will showcase and present to the patient. Once the patient is fully aware of the objective in surgery, the surgery will be scheduled.

SURGICAL IMPLANTATION

In surgery, Dr. Barnett will have a clear blueprint on where to cut, how much the cut, and how to fit the desired hardware. This preop design process will maximize accuracy and cut down on operating time. This is of a huge benefit by reducing tourniquet times and less anesthesia. Once the surgery is complete, Dr. Barnett will closely follow the patient in the clinic to see that the problem is fully resolved.

FINAL THOUGHTS

3D designed Surgery is not only safer for patients, but also more accurate to a more complete recovery. Have a metal allergy? We can design a plate you are not allergic to. Have a congenital problem that is extremely unique that premade hardware can not predict? We got that covered!

Imaging courtesy of Dr. Barnet, Mike Sganga DPM, and Paragon28